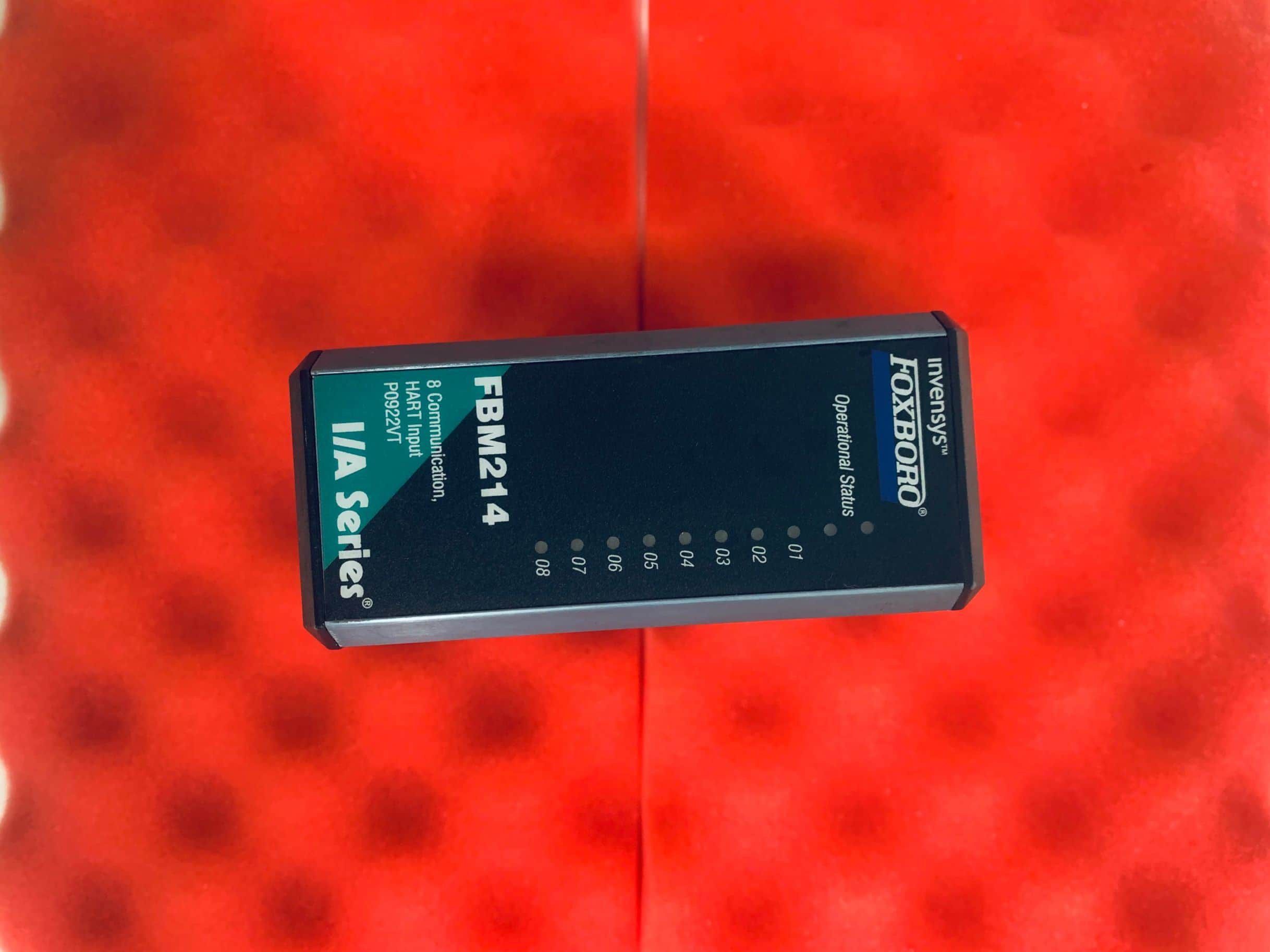

The Foxboro FBM214 is a communication input interface produced by Foxboro, which is a brand of Schneider Electric. The FBM214 module serves as an interface between the field devices and the I/A Series system, allowing for communication and integration of the field information into the control system.

Here are some key features and capabilities of the Foxboro FBM214 module:

Communication Protocol Support: The FBM214 module supports various communication protocols, such as Modbus and OPC (OLE for Process Control), allowing for interoperability with a wide range of field devices and systems.

Input Signal Acquisition: The module is capable of acquiring analog and digital signals from field devices, including sensors, transmitters, switches, and other instruments. It converts these signals into a digital format for further processing by the control system.

Data Transmission: The FBM214 module transmits the acquired data to the control system using the selected communication protocol. This data includes process values, status information, alarms, and other relevant data from the field devices connected to the module.

Configurability: The module is configurable to suit the specific requirements of the process or application. Engineers can set up parameters such as communication parameters, scaling factors, signal types, etc., to ensure accurate and reliable data acquisition.

Redundancy and Fault Tolerance: The FBM214 module supports redundancy configurations to ensure high availability and fault tolerance. Redundant communication paths and failover mechanisms can be implemented to maintain continuous communication and minimize downtime.

Integration with I/A Series System: The FBM214 module seamlessly integrates with the Foxboro I/A Series control system, enabling centralized monitoring, control, and analysis of the field data. The acquired data can be accessed and utilized by other system components, such as distributed control modules, historical data recorders, and advanced control strategies.

Overall, the Foxboro FBM214 module plays a crucial role in bridging the gap between the field devices and the control system, enabling efficient and reliable communication and integration of field data.

Foxboro FBM214 Communication Input Interface Module Datasheet

Foxboro FBM214 Communication Input Interface Module Datasheet Warranty

Warranty

Delivery Time

Delivery Time