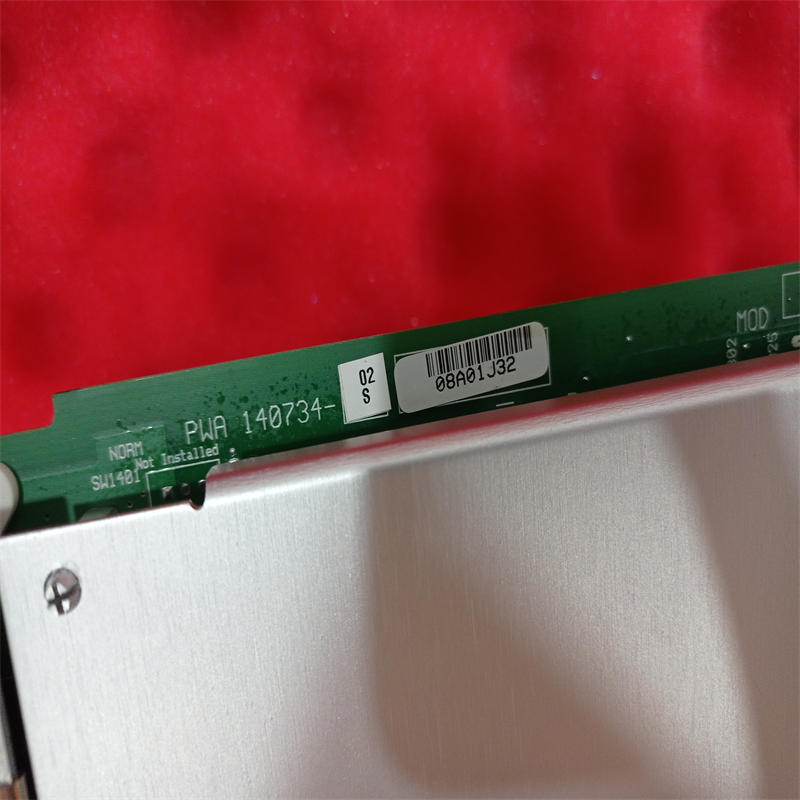

Bently Nevada 3500/42M Proximitor Seismic Monitor 140734-02

The Bently Nevada 3500/42M Proximitor Seismic Monitor, part number 176449-02 or 140734-02.

Item NO.:

3500/42M 140734-02Payment:

T/TMarket Price:

$430Product Origin:

United States (US)Product weight:

0.45kgLead Time:

In stockShipping Port:

Xiamen|

» Description |

| Manufacture | Bently Nevada |

| Model | 140734-02 |

| Product ID | 3500/42M |

| Catalog | 3500 Series Monitor System |

| Description | 3500/42M Proximitor Seismic Monitor 140734-02 |

| Country of Origin | United States (US) |

| Dimension | 241.3 mm x 24.4 mm x 90.8 mm |

| Weight | 0.45kg |

The Bently Nevada 3500/42M Proximitor Seismic Monitor, part number 176449-02 or 140734-02, is a specialized monitoring device used for measuring and analyzing vibrations or seismic activity in industrial machinery and equipment. It is specifically designed for critical machinery protection and condition monitoring applications.

The 3500/42M Proximitor Seismic Monitor is part of the GE Bently Nevada 3500 Series Monitoring System, which is widely used in industries such as oil and gas, power generation, petrochemical, and manufacturing. It provides real-time monitoring of vibrations and enables operators to detect and diagnose potential issues or anomalies in rotating machinery, such as turbines, compressors, pumps, and motors.

Key features of the 3500/42M Proximitor Seismic Monitor include:

1. Proximity Probe Inputs: It has four (4) channels for accepting signals from proximity probes, which are usually installed on or near the machinery being monitored. Proximity probes measure the relative shaft displacement, allowing the monitor to detect vibrations or axial position changes.

2. Seismic Channels: It includes four (4) seismic channels that are used for monitoring vibrations generated by the machine's base or casing. The seismic channels measure the overall vibration levels and can provide early warnings of potential machine failures.

3. Dynamic Monitoring: The monitor continuously monitors the machinery and provides real-time data on the vibration levels, which can be used for trend analysis and predictive maintenance strategies.

4. Alarm and Shutdown Capabilities: The 3500/42M Proximitor Seismic Monitor can be configured to trigger alarms, display warnings, or even initiate automatic shutdowns if the vibration or seismic levels exceed the pre-set thresholds. This helps protect the machinery from further damage and prevent catastrophic failures.

5. Communication Interfaces: The monitor is equipped with communication interfaces that allow it to connect to various monitoring and control systems, enabling remote monitoring and data integration with a broader plant-wide monitoring infrastructure.

Overall, the Bently Nevada 3500/42M Proximitor Seismic Monitor is a critical component in machine health monitoring systems, providing reliable and accurate data for machinery protection and enabling proactive maintenance practices to prevent costly and repairs.

|

Bently Nevada 3500/42M Proximitor Seismic Monitor 140734-02 Datasheet

Bently Nevada 3500/42M Proximitor Seismic Monitor 140734-02 Datasheet

Warranty

Warranty

Delivery Time

Delivery Time